Built for traceability, controlled workflows, and product safety

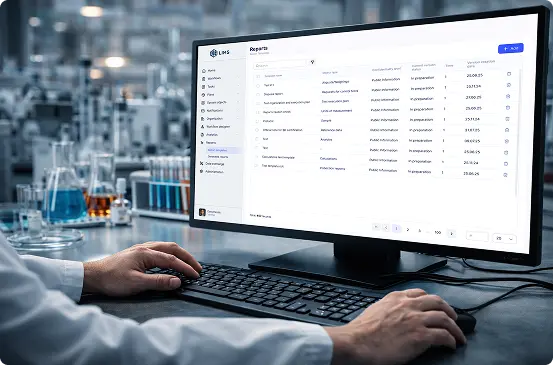

From raw material testing to final product release, TestPatron LIMS enables you to manage samples, results, approvals, and batch decisions across sites and production lines.

TestPatron LIMS enables food and beverage laboratories to address the following issues:

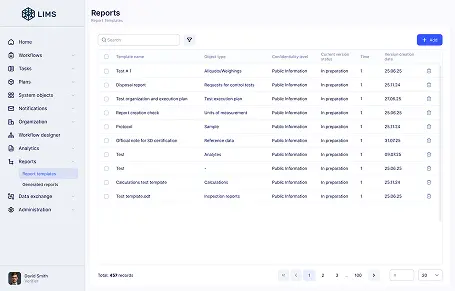

F&B labs generate complex, production-critical data: batch-linked test results, microbiology outcomes, shelf-life data, equipment usage, and quality trends. AI provides data insights instantly — without manual reports, spreadsheets, or business analyst effort.

Which batches were affected by out-of-spec results this week?

Show microbiological trends for this product over the last 6 months

Which instruments were used for batch X and were they within calibration?

Are there recurring deviations linked to a specific method or line?

What samples are currently blocking batch release?

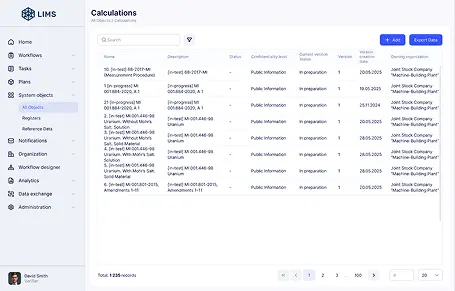

Batch hierarchies and product specifications

Method versions and acceptance criteria

Equipment status, calibration, and maintenance

Changes in lab structure, workflows, and sites

Integrated data from instruments and external systems

Faster batch release decisions without manual data consolidation

Early detection of trends before they become quality incidents

Full visibility for QA, QC, and production stakeholders

TestPatron LIMS is used by different types of food and beverage laboratories with overlapping but not identical workflows:

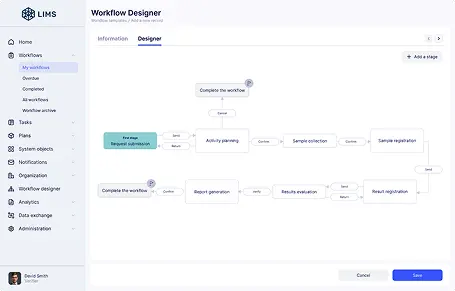

Instead of forcing all of F&B lab types into one rigid model, TestPatron LIMS adapts to each laboratory's real processes using no‑code configuration.

Contact us, and we'll show you how to adapt our test and measurement automation platform to your workflows and equipment.

Laboratories create digital test cases linked to product types, batch parameters, and internal specifications. Test execution, result entry, review, and approval are managed within a single system.

TestPatron LIMS provides:

Food and beverage laboratories differ by product lines, processes, and rules. TestPatron LIMS adapts to any needs without custom development. As a result, you can digitize SOPs, internal methods, and decision logic exactly as they are used in daily work.

Five built‑in designers allow you to configure:

Typical configuration takes 1–3 days, not months. Customizations don't require programming expertise.

Fill out the form and our specialists will contact you within 24 hours to discuss how LIMS platform can transform your laboratory workflows.